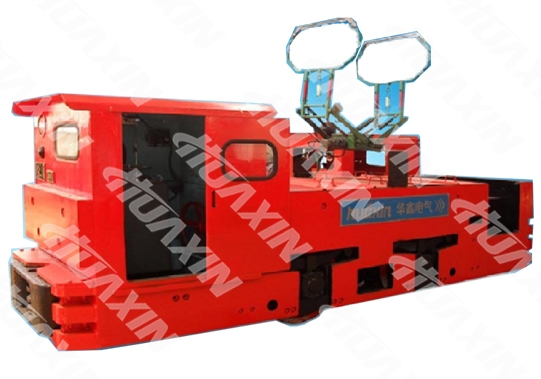

Overhead line electric locomotive

The overhead line mining electrical locomotive is manufactured according to MT/T 1064-200 Specification of Narrow Tramroad Gauge Electric Locomotive for Mine, and is applicable for the general metal ore and the coal mine free of methane or coal dust explosion hazard. It can be taken as the main traction equipment for mineral and material transport in the underground main roadway or adit. The locomotive is also installed with the wing plate, so as to adapt to demands for transport with the bottom-dump wagon.

Technical parameters IV. Technical parameters

Category

Project name

Technical data

CJY7/6.7.9GP

CJY10/6.7.9GP

CJY14/6.7.9GP

Traction characterized

Adhesion mass (t)

7

10

14

Traction motor power * number (KW×set)

22 × 2

30 × 2

45× 2

Hourly braking and tractive force (KN)

13.77

18.78

21.3

Maximum traction force (KN)

17.15

24.5

34.3

Hourly speed (km/h)

11

10.5

14.7

Traction height (mm)

320/435

320/435

320/435

Braking mode

Mechanical + electrical

Mechanical + electrical

Mechanical + electrical + air

Appearance feature

Gauge (mm)

600/762/900

600/762/900

600/762/900

Axle base (mm)

1100

1100

1700

Wheel rolling circle diameter (mm)

680

680

760

Minimum radius of curvature negotiated (m)

7

7

12

Height from the rail surface to the ceiling (mm)

1600

1600

1600

External dimensions (mm)

4480 ×1050 ×1600

4480 ×1212 ×1600

4480 ×1350 ×1600

4500 ×1050 ×1600

4500 ×1212 ×1600

4500 ×1350 ×1600

4950 ×1050×1600

4950 ×1212 ×1600

4950 ×1350 ×1600

Category

Project name

Technical data

CJY18/6.7.9GPY

CJY20/6.7.9GPY

Traction characterized

Adhesion mass (t)

18

20

Traction motor power * number (KW×set)

63 × 2

63× 2

Hourly braking and tractive force (KN)

37.2

37.2

Maximum traction force (KN)

44.1

49

Hourly speed (km/h)

11

11

Traction height (mm)

320/435

320/435

Braking mode

Mechanical + electrical

Mechanical + electrical

Appearance feature

Gauge (mm)

600/762/900

600/762/900

Axle base (mm)

1700

1700

Wheel rolling circle diameter (mm)

760

760

Minimum radius of curvature negotiated (m)

12

12

Height from the rail surface to the ceiling (mm)

1600

1600

External dimensions (mm)

5400 ×1040 ×1600

5400 ×1202 ×1600

4480 ×1340 ×1600

5400 ×1040×1600

5400 ×1202 ×1600

5400 ×1340 ×1600

1. Traction motor: three-phase asynchronous variable frequency motor, low construction cost, low failure rate, basically maintenance-free, high operation efficiency and strong applicability, it can realize parameter adjustment in different outlines, so as to realize design demands of the special model.

2. Controller: microcomputer control is adopted for speed control by frequency variation, the digital signal processor (DSP) is taken as the core, and frequency control, vector control and slippage rate are controlled perfectly, which belongs to stepless speed regulation. No mechanical maintenance workload.

3. Performance:

1) Start, speed regulation, coasting and brake of the locomotive is realized by changing the operating frequency through microcomputer control.

2) Downward speed regulation from fundamental frequency is constant torque speed regulation; upward speed regulation from fundamental frequency is constant power speed regulation.

3) The speed regulation scope is large, the rotating speed stability is good, and the frequency can be adjusted continuously, which is stepless speed regulation, and facilitates adhesion of the locomotive. The slippage rate is small with high efficiency during operation.

4) It can realize intelligent control and stable operation, and extends the service life of the mechanical component.

4. Energy consumption: speed control by frequency variation is constant torque output control at rated frequency, and the energy saving effects are quite obvious plus regenerative braking.

The locomotive is of two-axle steel frame type, which has the features of compact structure, stable operation and centralized control. It consists of the frame, cab, buffer, brake, braking mechanism, sanding mechanism, travel device, spring suspension system, electrical equipment system and other main parts.

1Mechanical part

The mechanical part mainly consists of the carbody, carbody accessories, travel device, braking mechanism, sanding device, cab, damping mechanism and buffer. The mechanical energy generated by the traction motor is transferred to the travel device, and provide the traction power to the locomotive, i.e., tractive force of the wheel flange.

2Carbody composition

The carbody is the frame structure welding the left and right side plates, front and rear end plates and intermediate diaphragm. The carbody is supported on the bearing box of the travel component through four groups of vibration dampers, and the carbody and the travel device are connected. The buffer is installed at the front and rear end plates of the carbody, so as to mitigate impact and couple the mine car.

3Travel device

The travel device consists of the reducer casing, wheelset, axle box and other parts. There are two groups of each locomotive. Transmission principle.

The reducer casing is casted with ZG230-450 and consists of the upper and lower halves. The upper casing and the traction motor shell are fitted with the rabbet, and connected with bolt. It is semi-suspended on the frame with the damping spring.

The wheelset consists of the wheel, wheel axle, bearing box and so on. The wheel consists of the wheel hub and wheel rim through press-fitting, the wheel and wheel axle are subject to cold press-fitting, a bearing box is installed at both ends of the wheel axle, the box is cast with ZG270-500, and it withstands the weight of all equipment of the locomotive. Locomotive traction in the horizontal direction is transferred to the carbody through the guide rail of the bearing box.

4Braking device

Mechanical brake and electric brake are adopted for the locomotive. The braking resistor arranged on the electric locomotive is mainly used for speed limit of the locomotive on the long slope or downhill. Mechanical brake is also required to completely stop the locomotive, so that the brake shoe is close to or separated from the wheel flange, so as to realize system brake or release.

The mechanical braking device is used on the locomotive or train for parking on the rampway. The drivers rotate the handwheel in the clockwise direction, so as to drive the crossbeam, pull rod and connecting rod through the screw rod and nut, and drive the brake shoe. Meanwhile, two groups of wheels are braked or released. After the brake shoe is worn, the brake shoe clearance regulator can be adjusted, so that the clearance of 2 to -3mm is maintained between the brake shoe and wheel flange. Adjust the spring leaf with the adjusting screw, so that the gap between the working surface of the brake shoe and the wheel tread is maintained uniform, so as to guarantee the braking effect.

5Sanding device

Manual sanding principle is utilized for the device, and there are four sand boxes near four wheels of the locomotive. Sanding can be conducted to the track when brake is applied to the locomotive, so as to increase adhesion coefficient between the wheel rim and rail surface. When the locomotive travels forward, front sanding is adopted; when the locomotive travels backward, rear sanding is adopted.

6 Cab

The cab is installed at the front of the cab. The cab roof consists of the roof, front board, left and right side plates and back plate, which is of the closed structure. It can prevent rainwater, falling rock and so on, so as to protect personnel safety of the driver. The observation window is opened at the front end of the, and the lighting signal lamp is installed. The controller, brake handwheel and so on are arranged in the cab.

7 Damping mechanism

The plate spring damping mechanism of CJY7/6, 7, 9GPY, CJY10/6, 7, 9GP overhead line mining electrical locomotive consists of four groups of plate springs, plate spring connecting rod and equalizing beam. It plays the role of damping. Each group of plate spring is located in the dimple of the axle box and is connected with the travel device through the boss at the bottom spring hoop. Both ends at the upper of the front two groups of plate springs are connected with the carbody through the plate spring connecting rod and the equalizing beam, and both ends at the upper part of the rear two groups of plate spring are connected with the carbody through the plate spring connecting rod. The front two groups of plate springs adjust the axle weight at both ends through the equalizing beam, which facilitates counterweight balancing of the whole vehicle.

CJY14/6, 7, 9GP, CJY18/6, 7, 9GPY, CJY20/6, 7, 9GPY, CJL18/6, 7, 9GP overhead line mining electrical locomotives adopt the rubber damper. The vibration damper shall be suspended on the left and right sides of the frame, and supported on the wheelset bearing box, so as to play the role of damping.

8Buffer

The buffer consists of the buffer frame, buffer seat, upper cover plate, head, spring and connecting pin. The buffer is installed on the front and rear end plates of the frame, which plays the role in coupling mine car and buffer, and can mitigate impact between the locomotive and the mine car.

Our offering

Case studies

Contact information

-

About Huaxin

-

Follow us

-

Share us

©1996-2017 晉ICP備07500050號 Huaxin Copyright

©2016-2017 晉ICP備07500050號 Huaxin Copyright