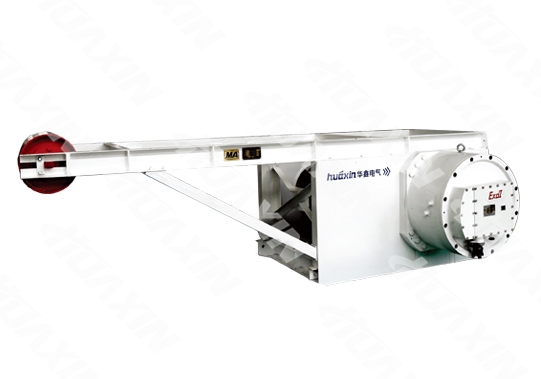

Permanent magnet direct-drive conveyor

The permanent magnet direct-drive conveyor has been proved by industrial tests that the parameters are reasonable, the structure is advanced, and it can fully meet the needs of underground transportation, and has been widely used in the major mines. The traditional belt conveyor system adopts asynchronous motor, hydraulic coupler and decelerator to transmit the power to the drum to drive the belt, and the obvious defects of this traditional transmission way include: The efficiency of driving system is low, and it starts unstably, and the heavy load start is difficult, directly affecting the overall efficiency of the driving system. Mine party maintains and replaces the decelerator, coupler and other parts frequently.

The driving system through technical transformation adopts the no-gear permanent magnet synchronous motor frequency conversion driving system, namely, the driving system consists of permanent magnet synchronous motor and frequency converter which are combined to realize the power transmission, and the driving system has the advantages of high efficiency, energy saving due to removal of the decelerator, hydraulic coupler; and low noise, “free” from maintenance; it also has the advantages of large output torque, smooth starting and constant torque control, etc.. Its successful research and development has made a useful exploration for our development of "green mining equipment" with independent intellectual property rights in the field of mining equipment.

Description of product model

S/N

Belt conveyor specifications

Conveying capacity

(t/h)

Belt speed

(m/s)

Belt width (mm)

Tape model

Main motor power

Diameter of driving pulley

Diameter of idler

1

DSJ100/80/160YB

800

2.5

1000

PVC1000S

160kW

630mm

108mm

2

DSJ100/80/2×200YB

800

2.5

1000

PVC1000S

2×200kW

630mm

108mm

3

DSJ100/80/2x160YB

800

2.5

1000

PVC1000S

2×160kW

630mm

108mm

4

DSJ100/90/2×250YB

900

2.5

1000

PVC1000S

2×250kW

630mm

108mm

5

DSJ100/90/2×315YB

900

2.5

1000

PVC1000S

2×315kW

630mm

108mm

6

DSJ100/95/2×355YB

950

2.5

1000

PVC1000S

2×355kW

630mm

108mm

7

DSJ100/95/2×400YB

950

2.5

1000

PVC1000S

2×400kW

630mm

108mm

8

DSJ120/100/250YB

1000

3.5

1200

PVC1400S

250kW

830mm

133mm

9

DSJ120/110/2×200YB

1100

3.5

1200

PVC1400S

2×200kW

830mm

133mm

10

DSJ120/130/315YB

1300

3.5

1200

PVC1400S

315kW

830mm

133mm

11

DSJ120/140/355YB

1400

3.5

1200

PVC1400S

355kW

830mm

133mm

12

DSJ120/150/2×250YB

1500

3.5

1200

PVC1400S

2×250kW

830mm

133mm

13

DSJ120/150/2×315YB

1500

3.5

1200

PVC1400S

2×315kW

830mm

133mm

14

DSJ120/150/400YB

1500

3.5

1200

PVC1400S

400kW

830mm

133mm

15

DSJ120/170/2×355YB

1700

3.5

1200

PVC1400S

2×355kW

830mm

133mm

16

DSJ120/180/2×400YB

1800

3.5

1200

PVC1400S

2×400kW

830mm

133mm

17

DSJ120/70/200YB

700

3.5

1200

PVC1400S

200kW

830mm

133mm

18

DSJ80/40/55YB

400

2

800

PVC800S

55kW

630mm

108mm

19

DSJ80/48/2×55YB

480

2

800

PVC800S

2×55kW

630mm

108mm

20

DTC80/15/200SYB

150

2

800

PVC1400S

200kW

830mm

108mm

21

DTC80/15/250SYB

150

2

800

PVC1400S

250kW

830mm

108mm

22

DTL100/100/2×355YB

1000

2.5

1000

PVC1400S

2×355kW

830mm

108mm

23

DTL100/120/2×400YB

1200

2.5

1000

PVC1400S

2×400kW

830mm

108mm

24

DTL100/70/2×250YB

700

2.5

1000

PVC1400S

2×250kW

830mm

108mm

25

DTL100/80/2×315YB

800

2.5

1000

PVC1400S

2×315kW

830mm

108mm

26

DTL120/110/2×355SYB

1100

3.5

1200

PVC1400S

2×355kW

1000mm

133mm

27

DTL120/130/2×400SYB

1300

3.5

1200

PVC1400S

2×400kW

1000mm

133mm

Improving transmission efficiency, reducing power consumption, the energy consumption of Y series asynchronous motor used in the traditional drive system only reaches the international level IE1 (equivalent to the national level III energy consumption). The energy consumption of permanent magnet synchronous motor used in the system has reached the international IE4 (higher than the national level I energy consumption standards). Similarly, a set of DSJ80 belt conveyor can save power for RMB one hundred thousand per year.

The system realizes soft starting and free maintenance. The system controls the starting with frequency converter and realizes the slow and uniform starting of the system transmission. At the same time, compared with the original system, it eliminates hydraulic coupler, decelerator and synchronous gear, so the maintenance cost can be saved for at least RMB 30,000.00 to 50,000.00 per year, accordingly reducing maintenance costs.

Realize power balance—When the system uses multi-motor master-slave control drive, power balance can be achieved to avoid the damage to the motor caused by multi-motor power imbalance.

Large starting torque—The permanent magnet synchronous motor of the system can constantly output the starting torque 2.8 times higher than the rated load torque, while the starting torque of the traditional asynchronous motor is 55% of the rated load.

- All document kinds>

- Product brochure

- Data sheet

- Software

- Technical publications

- Article

- Material specification

- Product brochure

Our offering

Case studies

Contact information

-

About Huaxin

-

Follow us

-

Share us

©1996-2017 晉ICP備07500050號(hào) Huaxin Copyright

©2016-2017 晉ICP備07500050號(hào) Huaxin Copyright