Fixed belt conveyor

The fixed belt conveyor is universal series product. It is a continuous conveying equipment with cotton canvas, nylon, polyester canvas and wire rope core conveyor belt as traction components. It can be widely used in coal, metallurgy, mining, port, chemical industry, light industry, petroleum, machinery and other industries, conveying various kinds of bulk materials and integrated articles with bulk density of 500-2,500 kg/m3.

The belt conveyor has the characteristics of large freight capacity, high climbing capacity, low operating cost, easy maintenance and so on, so it is easy to realize the automatic control of the conveying system.

The conveyor’s allowable material lumpiness for the conveyor belt varies, depending on the belt width, belt speed, groove angle, and inclination, as well as the occurrence frequency of the bulk material.

Working environment temperature: Generally, it is -25℃-+40℃, and for places with special requirements, such as high temperature, cold, explosion-proof, flame retardant, anti-corrosion, acid and alkali resistance, waterproof and other conditions, corresponding protective measures should be taken.

The fixed belt conveyor is designed according to the parts series. When selecting, carry out the type selection design, calculation and assembly into a complete set of machine according to the process line and different terrain and working conditions. The manufacturer shall produce and supply goods according to the general plan or list of parts. The designer is responsible for the whole machine’s performance and parameters and the manufacturer is responsible for the performance and quality of the components.

The conveyor should be installed in the corridor to the greatest extent. In the open air, the driving part should be equipped with protective cover.

This series of products can meet the requirements of horizontal, upward, downward movements and other conditions. It can also adopt the conveying form with the combination of convex arc section, concave arc section and straight line section.

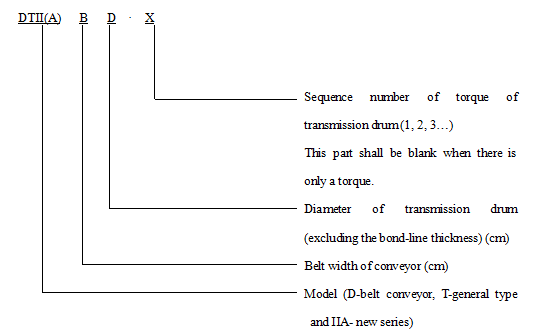

Description of product model

Vm/s

B mm

0.8

1.0

1.25

1.6

2.0

2.5

3.15

4

4.5

5

Conveying capacity IV m3/h

500

69

87

108

139

174

217

650

127

159

198

254

318

397

800

198

248

310

397

495

620

781

1000

324

405

507

649

811

1014

1278

1622

1200

593

742

951

1188

1486

1872

2377

2674

2971

1400

825

1032

1321

1652

2065

2602

3304

3718

4130

Note: 1. Conveying capacity IV value is calculated at the angle of move θ of 20 degrees, and trough angle of idler λ of 35 degrees, according to horizontal transport.

Fixed belt conveyor has the advantages of large conveying capacity, simple structure, easy maintenance, low costs and high versatility.

Smooth and steady conveying. No relative motion between materials and conveyor belt so that it can avoid from damaging materials conveyed.

Lower noise. Be suited to occasions of relatively quiet work environment.

Simple structure, convenient for maintenance.

Less energy consumption and low use costs.

The fixed belt conveyor is universal series product. It is a continuous conveying equipment with cotton canvas, nylon, polyester canvas and wire rope core conveyor belt as traction components. It can be widely used in coal, metallurgy, mining, port, chemical industry, light industry, petroleum, machinery and other industries, conveying various kinds of bulk materials and integrated articles with bulk density of 500-2,500 kg/m3.

Convey a variety of bulk materials and integrated articles whose bulk density is 500 to 2,500 kg/m3.

The applicable working environment temperature is generally -20 - 40℃. For the working environment with heat-resistant, cold-resistant, anti-corrosion, explosion-proof, flame retardant and other requirements, it is necessary to use special rubber conveyor belt and adopt corresponding protective measures. The conveying material temperature varies, depending on the conveyor belt, and the conveying material temperature of the ordinary conveyor belt is generally not higher than 60℃; heat resistant rubber belt can deliver high temperature materials below 120℃; when conveying acidic, alkaline, oily materials and materials with organic solvent properties, it is necessary to choose the rubber belt or plastic belt which is resistant to oil, acid and alkali.

- All document kinds>

- Product brochure

- Data sheet

- Software

- Technical publications

- Article

- Material specification

- Product brochure

Our offering

Case studies

Contact information

-

About Huaxin

-

Follow us

-

Share us

©1996-2017 晉ICP備07500050號 Huaxin Copyright

©2016-2017 晉ICP備07500050號 Huaxin Copyright