Fixed Belt Conveyor

The Fixed Belt Conveyor is a universal series. It is a continuous conveying equipment with a cotton canvas, nylon, polyester canvas and wire rope conveyor belt as the traction component. It can be widely used in coal, metallurgy, mining, port, chemical industry, light industry, petroleum, machinery and other industries, conveying various kinds of bulk and packaged materials with a bulk density range of 500-2,500 kg/m3.

This belt conveyor has the advantages of large conveying capacity, high climbing capacity, low operating cost, easy maintenance, etc., furthermore, it is convenient to realize the automatic control of the delivery system.

The allowed size and weight of the conveying materials depends on the belt width, belt speed, groove angle, and inclination of the conveyor, as well as the frequency of conveying large bulk materials.

The applicable working environment temperature is generally between -40℃(-40℉) and 40℃(104℉). For those who requires a heat-resistant, cold-resistant, explosion-proof, flame-resistant, anti-corrosion, acid & alkaline-resistant, and/or water-proof working environment, protective measures should be taken accordingly.

The Fixed Belt Conveyor is designed by each part series. It can be customized, calculated, assembled into a complete conveyor according to different operational paths, terrains, and working conditions. Our manufacturer will produce and supply the Fixed Belt Conveyor(s) according to your needs. The designer is responsible for the performance parameters of the complete machine and the manufacturer is responsible for the performance and quality of the parts.

The conveyor should better be installed in the corridor. If installed in the open air, the driving device should be equipped with a protective cover.

This series of products can meet the requirements of horizontal, upward, downward, and other movements. It can also adopt the combination of convex, concave and straight line for diliverying.

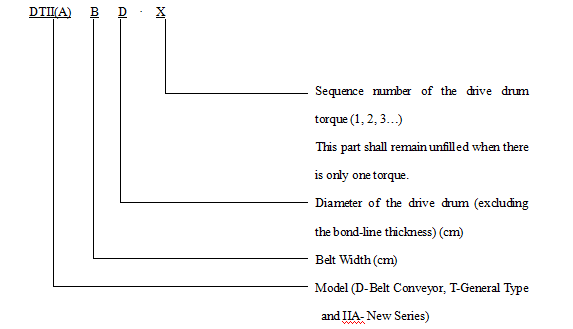

Description of Product Model

S/N

Belt Conveyor Specifications

Conveying Capacity

(t/h)

Belt Speed

(m/s)

Belt Width

(mm)

Belt Type

Main Motor Power

(kW)

Diameter of Drive Drum (mm)

Diameter of Idler

(mm)

1

DSJ100/80/160YB

800

2.5

1000

PVC1000S

160

630

108

2

DSJ100/80/2×200YB

800

2.5

1000

PVC1000S

2×200

630

108

3

DSJ100/80/2x160YB

800

2.5

1000

PVC1000S

2×160

630

108

4

DSJ100/90/2×250YB

900

2.5

1000

PVC1000S

2×250

630

108

5

DSJ100/90/2×315YB

900

2.5

1000

PVC1000S

2×315

630

108

6

DSJ100/95/2×355YB

950

2.5

1000

PVC1000S

2×355

630

108

7

DSJ100/95/2×400YB

950

2.5

1000

PVC1000S

2×400

630

108

8

DSJ120/100/250YB

1000

3.5

1200

PVC1400S

250

830

133

9

DSJ120/110/2×200YB

1100

3.5

1200

PVC1400S

2×200

830

133

10

DSJ120/130/315YB

1300

3.5

1200

PVC1400S

315

830

133

11

DSJ120/140/355YB

1400

3.5

1200

PVC1400S

355

830

133

12

DSJ120/150/2×250YB

1500

3.5

1200

PVC1400S

2×250

830

133

13

DSJ120/150/2×315YB

1500

3.5

1200

PVC1400S

2×315

830

133

14

DSJ120/150/400YB

1500

3.5

1200

PVC1400S

400

830

133

15

DSJ120/170/2×355YB

1700

3.5

1200

PVC1400S

2×355

830

133

16

DSJ120/180/2×400YB

1800

3.5

1200

PVC1400S

2×400

830

133

17

DSJ120/70/200YB

700

3.5

1200

PVC1400S

200

830

133

18

DSJ80/40/55YB

400

2

800

PVC800S

55

630

108

19

DSJ80/48/2×55YB

480

2

800

PVC800S

2×55

630

108

20

DTC80/15/200SYB

150

2

800

PVC1400S

200

830

108

21

DTC80/15/250SYB

150

2

800

PVC1400S

250

830

108

22

DTL100/100/2×355YB

1000

2.5

1000

PVC1400S

2×355

830

108

23

DTL100/120/2×400YB

1200

2.5

1000

PVC1400S

2×400

830

108

24

DTL100/70/2×250YB

700

2.5

1000

PVC1400S

2×250

830mm

108

25

DTL100/80/2×315YB

800

2.5

1000

PVC1400S

2×315

830mm

108

26

DTL120/110/2×355SYB

1100

3.5

1200

PVC1400S

2×355

1000mm

133

27

DTL120/130/2×400SYB

1300

3.5

1200

PVC1400S

2×400

1000mm

133

Improve drive efficiency and reduce power consumption. In the traditional drive system, the Y Series Asynchronous Motor is rated as IE1- Standard Efficiency; whereas in this new drive system, the Permanent Magnet Synchronous Motor is rated as IE4-Super Premium Efficiency. By using an IE4 rated Permanent Magnet Synchronous Motor, a DSJ80 belt conveyor can save up to 100,000 kWh per year compared to the same belt conveyor with an IE1 Y Series Asynchronous Motor.

The new system features a soft starter and is maintenance-free. It also uses a VFD to control the starting process, which allows the system to be up and running in a slow and uniform way. In addition, compared with the traditional system, the new system eliminates the hydraulic coupler, speed reducer, and synchronous gear, which could save substantial maintenance costs.

1. Smooth and steady conveying. No relative movement occurs between materials and the conveyor belt, so it can avoid materials from being damaged during conveying.

2. Lower noise. Right for relatively quiet working environment.

3. Simple structure, maintenance-friendly.

4. Less energy consumption and lower operating costs.

The Fixed Belt Conveyor is a universal series. It is a continuous conveying equipment with cotton canvas, nylon, polyester canvas and wire rope core conveyor belt as traction components. It can be widely used in coal, metallurgy, mining, port, chemical industry, light industry, petroleum, machinery and other industries, conveying various kinds of bulk materials and integrated articles with bulk density of 500-2,500 kg/m3.

Convey a variety of bulk and packaged materials with a density range of 500 to 2,500 kg/m3.

The applicable working environment temperature is generally between -40℃(-40℉) and 40℃(104℉). For those who require a heat-resistant, cold-resistant, anti-corrosion, explosion-proof, and/or flame-resistant working environment, a special rubber conveyor belt should be used and protective measures should be taken accordingly. Different conveyor belts have different required temperature to convey materials. The temperature of the conveying materials should not be higher than 60℃(140℉) when using a standard conveyor; the temperature of the conveying materials can reach up to 120℃(248℉) when using a heat-resistant rubber belt conveyor; when conveying acidic, alkaline, oily materials and/or materials with organic solvent nature, it is necessary to choose an oil-resistant, acid-resistant, and alkali-resistant rubber or plastic belt conveyor.

-

All document kinds >

-

Product brochure

-

Data sheet

-

Software

-

Technical publications

-

Article

-

Material specification

-

Product brochure

Our offering

Case studies

Contact information

-

About Huaxin

-

Follow Us

-

Share Us

©1996-2017 晉ICP備07500050號 Huaxin Copyright

©2016-2017 晉ICP備07500050號 Huaxin Copyright