35kv oil-immersed power transformer

The high-quality cold-rolled silicon steel sheet is adopted for 35KV three-phase oil-immersed power transformer, ladder three-stage seam is adopted, and the surface is coated with curing paint, which effectively reduces loss and noise; The coil is wound with high-quality oxygen-free copper conductor, the novel oil duct structure is adopted for radiation, which has reasonable design, optimizes the insulation process, and improves mechanical strength and anti-short circuit ability. It has artistic and generous outline, and is widely used in the transformer substation (station) and urban and rural power grid.

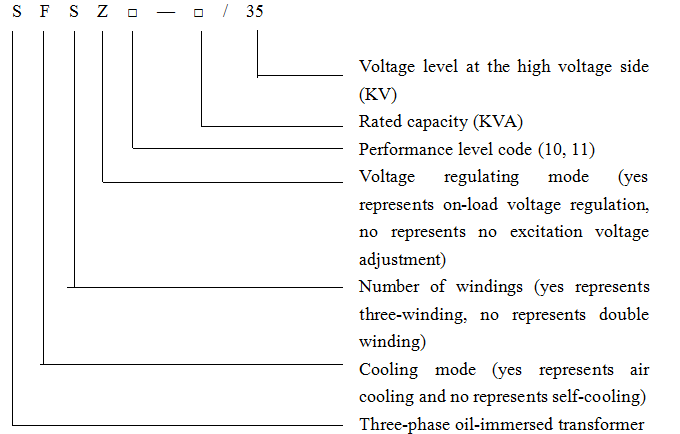

Model description:

Technical parameters:

1. Rated capacity: see Table 1, Table 2 and Table 3:

2. Rated voltage: see Table 1, Table 2 and Table 3:

3. Rated frequency 50 Hz

4. Number of phases: 3 phases;

5. Cooling mode; oil-immersed natural cooling(ONAN);

6. Temperature resistance level of the insulation materials: Level A;

7. Technical performance data and coupling group number: see Table 1, Table 2 and Table 3.

Table 1 Double winding no excitation voltage adjustment distribution transformer

Rated capacity (kVA)

Voltage combination (kV)

Coupling group

No-load loss (W)

Load loss (W) (75℃)

Short-circuit impedance (%)

No-load current (%)

High-voltage (KV)

Tapping (%)

Low-voltage (KV)

50

35 38.5

±5

±2×2.50.4

Dyn11 Yyn0

160

1200/1140

6.5

1.6

1.3

100

230

2010/1910

1.4

1.1

125

270

2370/2260

1.4

1.1

160

280

2820/2680

1.3

1

200

340

3320/3160

1.2

1

250

400

3950/3760

1.1

0.95

315

480

4750/4530

1.1

0.95

400

580

5740/5470

1

0.85

500

680

6910/6580

1

0.85

630

830

7860

0.9

0.65

800

980

9400

0.8

0.65

1000

1150

11500

0.8

0.65

1250

1400

13900

0.7

0.6

1600

1690

16600

0.6

0.6

Note: for the transformer with the rated capacity of 500KV and below, the load loss above the slash in the table is only applicable for Dyn11 connection group, and the load loss value below the slash is applicable for Yyn0 connection group.

Table 2 Double winding no excitation voltage adjustment distribution transformer

Rated capacity (kVA)

Voltage combination (kV)

Coupling group

Idle load loss (W)

Load loss (W) (75℃)

Short-circuit impedance (%)

No-load current (%)

High-voltage (KV)

Tapping (%)

Low-voltage (KV)

800

35

±2×2.5

±53.15 6.3 10.5

Yd11

980

9400

6.5

0.8

0.65

1000

1150

11500

0.8

0.65

1250

1400

13900

0.72

0.55

1600

1690

16600

0.64

0.45

2000

2170

18300

0.56

0.45

2500

2500

19600

0.48

0.45

3150

35~38.5

3040

23000

7

0.45

0.45

4000

3610

27300

0.45

0.45

5000

4320

31300

0.38

0.45

6300

5240

35000

7.5

0.38

0.45

8000

±2×2.5

3.5

3.3

6.3 6.6

10.5YNd11

7200

38400

0.34

0.35

10000

8700

45300

0.34

0.35

12500

10000

53800

8

0.32

0.3

16000

12100

65800

0.32

0.3

20000

14400

79500

0.32

0.3

Note: for the transformer with low voltage of 10.5KV, the product with coupling group grade of Dyn11 can be provided.

Table 3 Double winding on-load-tap-changing transformer

Rated capacity (kVA)

Voltage combination (kV)

Coupling group

Idle load loss (W)

Load loss (W) (75℃)

Short-circuit impedance (%)

No-load current (%)

High-voltage (KV)

Tapping (%)

Low-voltage (KV)

2000

35

±3×2.5

6.3 10.5

Yd11

2300

19200

6.5

0.64

0.5

2500

2720

20600

0.64

0.5

3150

35~38.5

3230

24700

7

0.58

0.5

4000

3870

29100

0.58

0.5

5000

4640

34200

0.54

0.5

6300

5630

36700

8

0.54

0.5

8000

6.3

6.6

10.5YNd11

7870

40600

0.48

0.4

10000

9280

48000

0.48

0.4

12500

10900

56800

0.45

0.35

16000

13100

70300

0.43

0.35

20000

15500

82700

0.43

0.35

25000

18300

97800

10

0.4

0.3

Note: for the transformer with low voltage of 10.5KV, the product with coupling group grade of Dyn11 can be provided.

Table 1 Double winding no excitation voltage adjustment distribution transformer

Rated capacity (kVA)

External dimensions (mm) L × W × H

Weight (kg)

Gauge (mm)

Machine weight

Oil weight

Total weight

50

1150×720×1200

230

320

680

550×550

100

1200×740×1300

380

400

980

550×550

125

1250×780×1380

440

430

1100

550×550

160

1300×800×1400

510

460

1200

660×660

200

1400×840×1500

620

500

1400

660×660

250

1530×860×1580

690

530

1500

660×660

315

1600×890×1630

820

570

1680

660×660

400

1730×950×1700

930

650

1950

660×660

500

1800×980×1800

1070

710

2300

820×820

630

1900×1000×1850

1320

830

2650

820×820

800

1950×1060×1900

1570

900

3100

820×820

1000

1980×1100×1950

1800

1080

3750

820×820

1250

2010×1160×1980

2100

1150

4050

820×820

1600

2040×1310×2000

2550

1250

4730

820×820

Table 2 Double winding no excitation voltage transformer

Rated capacity (kVA)

External dimensions (mm) L × W × H

Weight (kg)

Gauge (mm)

Machine weight

Oil weight

Total weight

800

2020×1360×2400

1510

890

3250

820×820

1000

2180×1380×2550

2060

1040

3780

1070×1070

1250

2220×1300×2520

2150

1090

3890

1070×1070

1600

2270×1340×2450

2430

1140

4450

1070×1070

2000

2250×1380×2210

2820

1420

5670

1070×1070

2500

2300×1400×2300

3330

1550

6100

1070×1070

3150

2520×2720×2550

3670

1630

7100

1070×1070

4000

2800×2250×2500

4500

1830

8250

1070×1070

5000

3000×2370×2800

5255

1900

9120

1070×1070

6300

2830×3020×2920

6650

2250

11200

1070×1070

8000

3300×2970×3050

9470

3160

15200

1475×1475

10000

3250×2850×3000

10180

3050

17000

1475×1475

12500

3500×2930×3500

11000

3660

18800

1475×1475

16000

3620×3040×3600

13650

4250

22200

1475×1475

20000

3900×3650×3540

15200

5250

26750

1475×1475

Table 3 Double winding on-load tap changer

Rated capacity (kVA)

External dimensions (mm) L × W × H

Weight (kg)

Gauge (mm)

Machine weight

Oil weight

Total weight

2000

2600×1800×2785

3100

1800

6100

1475×1475

2500

2700×1900×2970

3570

1850

7000

1475×1475

3150

3390×2170×3040

4805

2575

8850

1475×1475

4000

3100×3000×3150

4470

2320

9250

1475×1475

5000

3100×3000×3450

5550

2550

10800

1475×1475

6300

3320×3350×2980

6450

2860

12300

1475×1475

8000

3470×3130×3550

7970

3150

14720

1475×1475

10000

4596×3670×3735

10250

5275

20655

1475×1070

12500

4945×3550×3720

13385

5985

24185

1475×1475

16000

4940×3550×4457

14690

7025

27835

1475×1475

20000

4950×3945×4025

17250

7565

31325

1475×1475

25000

5100×3640×4220

20995

8530

36510

1475×1475

Note: the external dimensions shall be subject to actual dimensions of the transformer.

1. Iron core: 30Q130 high permeability silicon steel sheet is adopted. The advanced step multi-laminated mode is adopted, which effectively reduces no-load loss, no-load current and noise;

2. Winding: the oxygen-free copper conductor with high electric conductivity is adopted for the electromagnetic wire, and the new process of overall package of the cylinder type, double pie type and novel screw type is adopted for winding, so that the product structure is more compact. Main insulation can be effectively guaranteed, the first and tail layers are reinforced, and insulation property is improved. The outer surface of winding is wound with high-strength shrinkable tape, which improves mechanical strength of the winding, and greatly improves impact resistance and anti-short circuit ability of the product;

3. Body: the body insulation pad is supported with the high-strength laminated wood and laminated paper board, so that the supporting area at the winding end reached over 95%, so as to further improve product anti-short circuit ability, and improve product operation reliability. The stiff belt buffer structure is adopted for connection between the body and the box cover, so as to overcome the phenomena of 'suspension' and 'top cover'. The insulation material is wrapped with the high-strength and high-density cable paper, and the allowed pressure is 45Mpa;

4. Oil tank: the radiating pipe is adopted for the oil tank (the inserting piece is adopted for the double-row and three-row oil pipe), or the ladder finned radiator is adopted, so as to increase the heat-sinking capability in the same tank wall area; the finned radiator or corrugated tank and the forced oil air cooling or forced oil water-cooled heat sink shall also be installed according to users' requirements. Surface treatment of the oil tank: 'conformal coating' (salt fog proof, warm proof and mold proof), the adhesion force of the top coat and the primer is strong, decoration is good, the thin film oil resistance, corrosion resistance, gloss retention and color retention are good, and it has good leveling property and covering power;

5. Chosen components: the pressure relief valve, signal thermometer, gas relay and so on are installed according to standard requirements, so as to guarantee safe operation of the transformer;

6. The series products have artistic appearance and small volume, which can reduce the floor area for installation, and are the ideal maintenance-free high-quality products.

Meanwhile, we make many improvement based on traditional structure and mature technology, such as: helical winding with longitudinal oil duct, better internal radiation; effective support of the coil end surface is improved, and resistance to short-circuit current is stronger; the new lifting structure and body positioning structure are adopted, so as to guarantee more reliable long-distance transport and operation.

-

About Huaxin

-

Follow us

-

Share us

©1996-2017 晉ICP備07500050號 Huaxin Copyright

©2016-2017 晉ICP備07500050號 Huaxin Copyright