The Direct-drive PC Pump Motor

The HXL series high-efficient intelligent Direct-drive PC Pump Motor has a rated power of 12.6 to 50 kW. Compared with the traditional ground direct drive screw pump, the belt and the speed reducer are removed, and system operation is stable. There is almost maintenance-free except for daily bearing lubrication. The failure rate is lower than that of the traditional belt drive, and repairing is time and labor saving. The key component is made of rare earth permanent magnet motor, and the motor can be replaced for free in case of demagnetization within 10 years, which greatly reduces repair cost of the user at the later stage.

The HXL series high-efficient intelligent Direct-drive PC Pump Motor has a rated power of 12.6 to 50 kW. Compared with the traditional ground direct drive screw pump, the belt and the speed reducer are removed, and system operation is stable. There is almost maintenance-free except for daily bearing lubrication. The failure rate is lower than that of the traditional belt drive, and repairing is time and labor saving. The key component is made of rare earth permanent magnet motor, and the motor can be replaced for free in case of demagnetization within 10 years, which greatly reduces repair cost of the user at the later stage.

Huaxin is the first manufacturing enterprise that researches, develops, obtains patent of and manufactures the explosion-proof permanent magnet motor for mining in China, and related products have been sold to the coal enterprises in Shanxi, Shandong, Gansu, Heilongjiang, Inner Mongolia and other regions in the country.

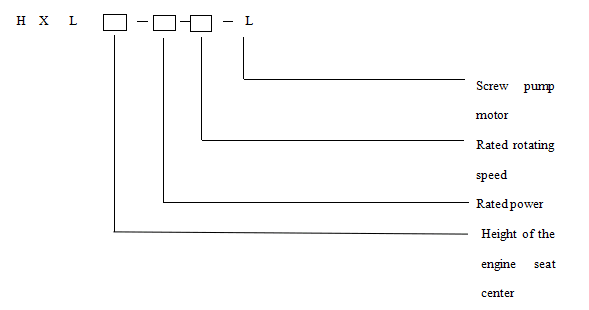

Model Description

Model description for TYC series high-efficient intelligent ground direct drive screw pump equipment

Technical Parameters

Model

Motor Parameters

Rated

Torque

Rated

Rotating Speed

(r/min)

Working

System

Rated

Power (Kw)

Number

of Pole

Pairs

(P)

Rated

Frequency

(Hz)

Wiring

Mode

Insulation

Level

Protection

Level

HXL280-12.6-200-L

600

200

S1

12.6

12

40

Y

F

IP54

HXL280-18.9-200-L

900

200

S1

18.9

12

40

Y

F

IP54

HXL280-23.1-200-L

1100

200

S1

23.1

12

40

Y

F

IP54

HXL280-28.3-200-L

1350

200

S1

28.3

12

40

Y

F

IP54

HXL280-31.5-200-L

1500

200

S1

31.5

12

40

Y

F

IP54

HXL280-40-200-L

1910

200

S1

40

12

40

Y

F

IP54

HXL280-50-200-L

2355

200

S1

50

12

40

Y

F

IP54

1. Compared with the traditional ground direct drive screw pump, The Direct-drive PC Pump Motor has obvious advantages as follows:

A. Strong overload capability, long duration, preventing a big horse pulling a small carriage, excellent performance

B. Soft start technology with reliable shutdown, preventing high-speed reverse rotation, good safety

C. The center of gravity is concentric with oil well without yawing, which effectively reduces the problem of packing leakage

D. Stable operation, maintenance-free, no speed reducer gearbox and the belt, easy to operate

E. Low operating noise, suitable for urban areas, especially for operation in the residential area

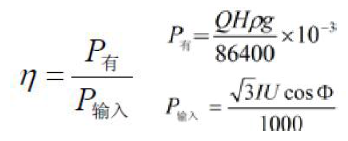

High system efficiency, obvious energy saving, the formula is as follows:

in which: ? - Screw pump system efficiency, %;

P有 - Screw pump effective power, kW;

Q - Oil well fluid production rate, m3/d;

H - Effective lift, m;

p - Oil well fluid density, kg/m3;

g - Gravity acceleration, 9.8 m/s2;

P輸入 - Screw pump input power, kW;

I - Measured current value, A;

U - Measured voltage value, V;

cos φ - Power factor.

2. Compared with the traditional ground direct drive screw pump - efficiency analysis of both equipment

The efficiency of the asynchronous motor of the traditional driving equipment is 75%, and the power factor is 0.4. The transmission efficiency of the general belt is 92% and the gear efficiency of the reducer casing is 92%. Therefore, the efficiency of the traditional mechanical screw pump is only: 75%x92%x92%=63.5%.

The efficiency of the direct-drive permanent magnet synchronous motor is generally 90% (calculation coefficient of 90%), the frequency converter efficiency is 95% to 97% (calculation coefficient of 96%), and the reactive power saving is 5%. Therefore, the efficiency of the direct-drive screw pump motor is: 90%x96%=86.4%.

Therefore, compared with the traditional mechanical screw pump, the direct-drive screw pump saves power by 23%.

3. Compared with the traditional ground direct drive screw pump - efficiency analysis of both equipment

Well Number

Type

Current

Voltage

Daily Fluid

Production Rate

Water Content Rate

Dynamic Liquid Level

Oil Pressure

(A)

(V)

(t)

(%)

(m)

(MPa)

L3-2935

Screw

26

266

35.69

97.5

531.25

0.4

L4-P281

Screw

29

282.6

74.27

94.72

418.11

0.43

L3-P291

Straight

11

280.8

51.46

94.00

361.98

0.26

L3-2917

Straight

7

279

31.07

95.50

375.29

0.29

Select the measured data of both equipment with similar production conditions

Comparison of current and daily fluid production rate (above table)

It can be seen from comparison in the table that the system efficiency of the direct-drive device is improved by 12.5% than that of the belt driving device, and power is saved by 32%. It is consistent with the theoretical analysis results. Therefore, power saving of the direct-drive screw pump is obvious, realizing production increase and consumption reduction!

4. Comparison of Repair and Maintenance

The belt and speed reducer units are removed from ground direct drive screw pump, and the system operation is stable. It is maintainance-free except for daily bearing lubrication. The failure rate is lower than that of the traditional belt drive, and it is time-saving and effort-saving for repairing. The key component is the rare earth permanent magnet motor, the motor can be replaced for free in case of demagnetization within 10 years, and repair cost at the later stage is greatly reduced.

HXL series high-efficient intelligent Direct-drive PC Pump Motor is widely applied in the mine, petroleum, building materials and other industries as the power input mechanism.

1. Elevation Height: ≤ 1000m.

2. Environmental Temperature: -60℃ to 60℃ (-76°F to 140°F).

3. Frequency: 0 to 50Hz.

4. Limit Value of Stator Winding Temperature Rise (Resistance Method): ≤ 80K

5.Protection Class: IP54.

-

All document kinds >

-

Product brochure

-

Data sheet

-

Software

-

Technical publications

-

Article

-

Material specification

-

Product brochure

Contact information

-

About Huaxin

-

Follow Us

-

Share Us

©1996-2023 晉ICP備07500050號(hào) Huaxin Copyright

©1996-2023 晉ICP備07500050號(hào) Huaxin Copyright